-

302022.06

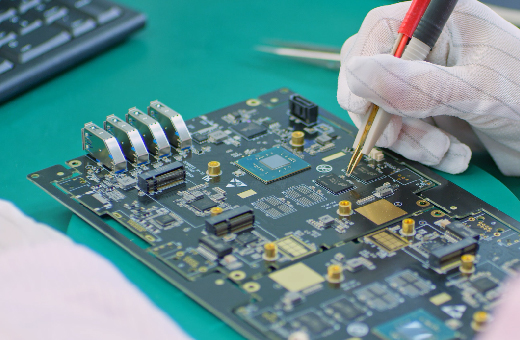

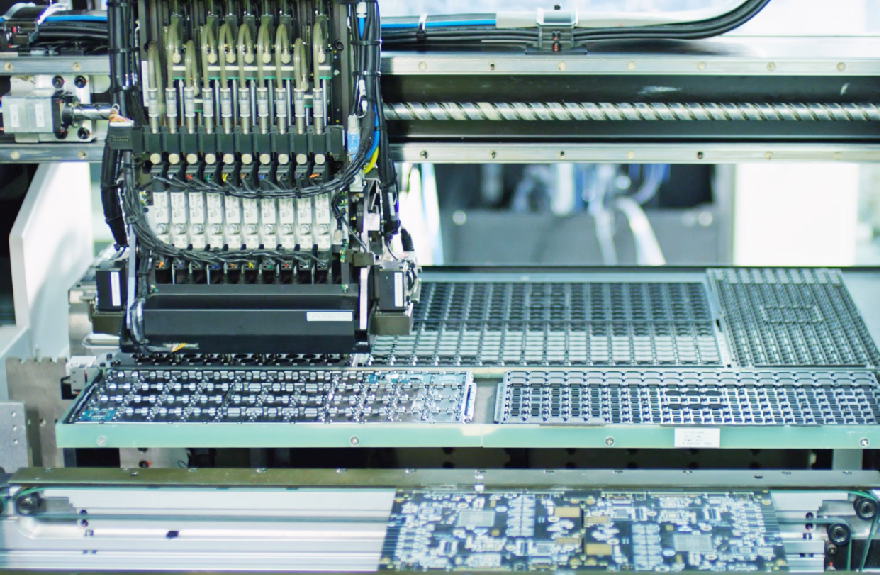

The SMT production progressing

SMT (Surface Mounted Technology) is the most popular Technology and process in electronic assembly industry. SMT refers ···Learn More → -

302022.06

AOI INSPECTION FOR PCB ASSEMBLY APPLICATIONS IN FACTORY

AOI technology is a process that allows manufacturers to inspect PCBs by applying an AOI inspection platform. This type ···Learn More → -

302022.06

PCB Assembly: Through-Hole Vs. Surface Mount

PCB assembly services have been arguing the benefits and drawbacks of through-hole vs. surface mount technologies since ···Learn More → -

302022.06

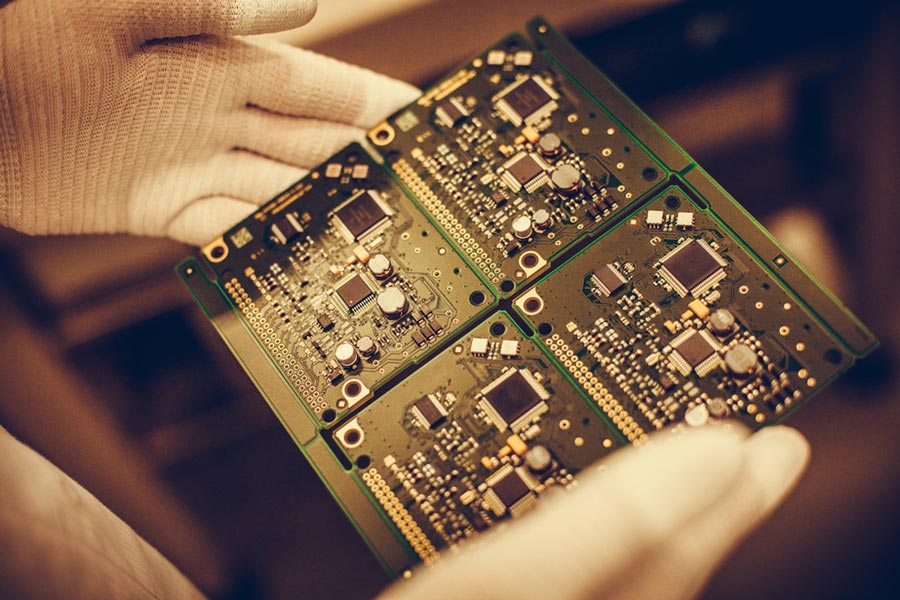

PCB Assembly: ESD-Sensitive Components in Electronic Circuits

Electrostatic discharge (ESD) occurs when any charged body attempts to become electrically neutral. During ESD, the stat···Learn More → -

292022.06

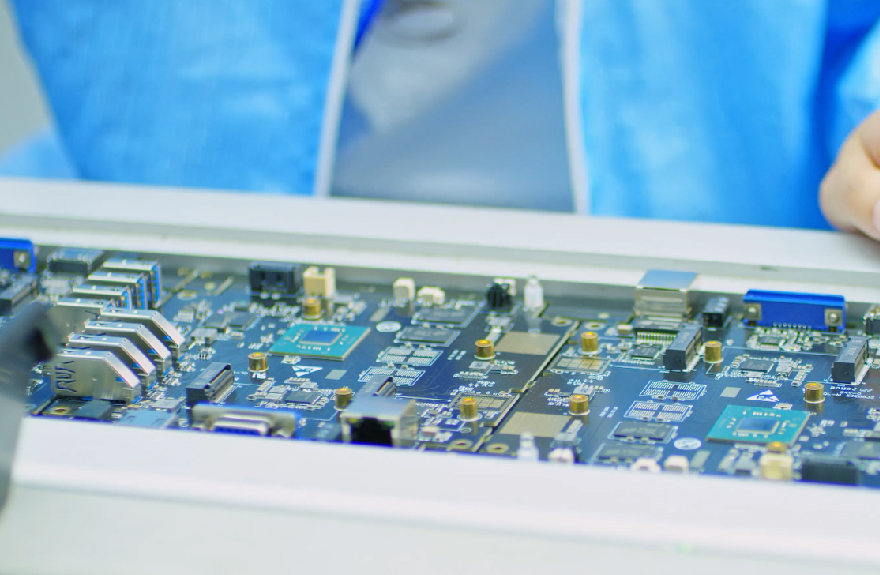

How to improve SMT processing efficiency in PCBs factory

SMT production requires a variety of production and testing equipment, which is a multi process process.If the connectiv···Learn More → -

292022.06

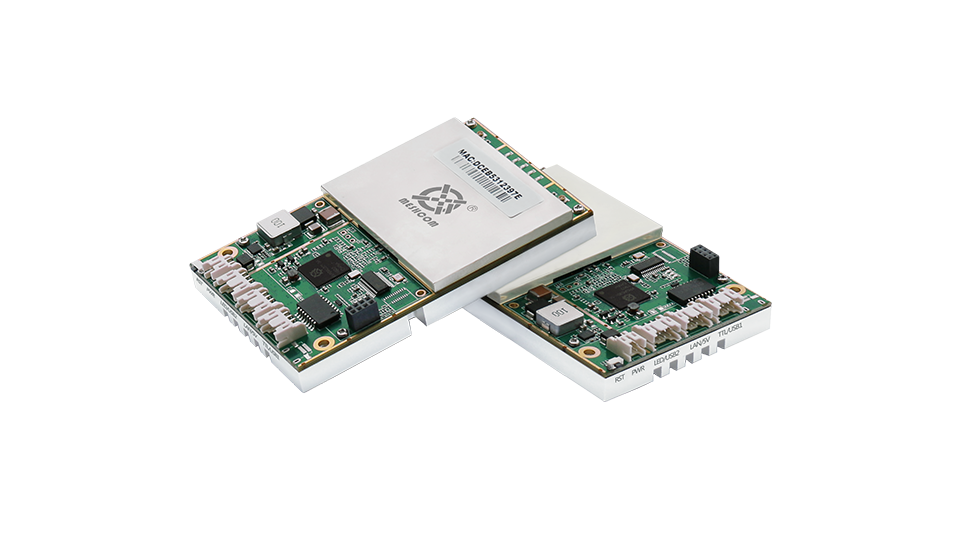

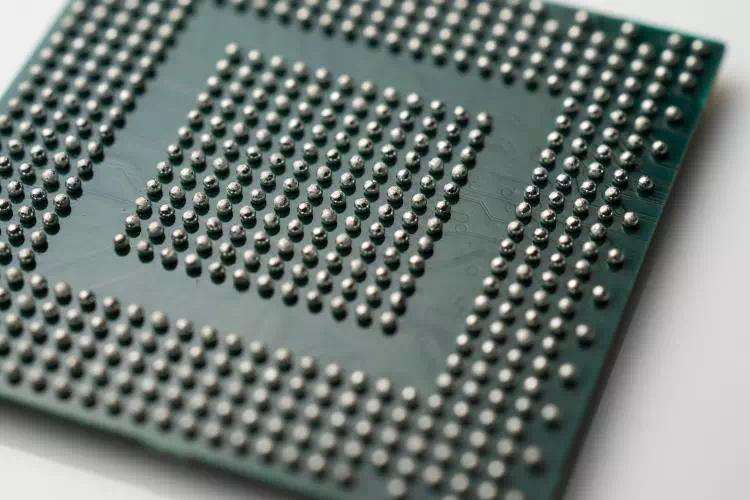

What is BGA Assembly

What is BGA and BGA assembly?BGABGA is a short form for Ball Grid Array. It is a high-performance, small-size, and light···Learn More → -

062022.04

Build a New Product quickly with PCB Assembly Prototyping – A Brief Guide!

Before you start a full production run, you want to be sure that your PCB is functioning correctly. After all you cannot···Learn More → -

262021.07

Pcb Assembly Reflow Soldering Temperature Control Requirements

Ensuring that the temperature curve of the reflow soldering process meets the temperature requirements of the product an···Learn More → -

262021.07

Pcb Manufacturing Incoming Material Inspection

I.PCB size and appearance inspectionPCB dimension testing mainly includes the diameter, spacing and tolerances of machin···Learn More →